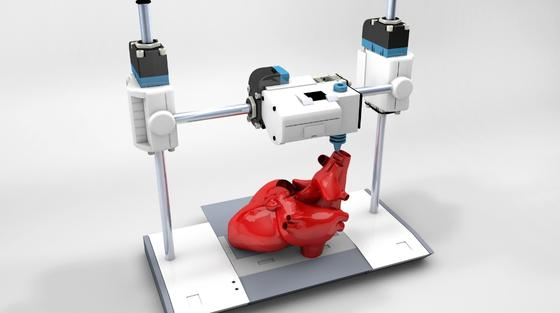

3D printing, also known as additive manufacturing, has revolutionized many industries, including medical device manufacturing. This revolutionary method stacks items in layers to create complex designs with exceptional precision and customization. 3D printing is revolutionizing the design, production, and delivery of medical devices. It has the potential to transform the medical device manufacturing industry and improve patient outcomes by lowering prices, accelerating production, and providing patients with personalized devices.

From Traditional Manufacturing to Additive Manufacturing

Subtractive manufacturing processes, such as machining and molding, are time-consuming and expensive, and they limit the design freedom of medical device manufacturing. 3D printing adds material layer by layer based on a digital model, enabling previously impossible complex geometries or those too expensive to produce. Additive manufacturing enables lightweight, strong, and precise medical devices to be produced with high precision. The ability to rapidly prototype and iterate designs accelerates development and enables manufacturers to adapt to changing healthcare needs.

Custom and Patient-Specific Devices

Customizing devices to specific patients is one of the biggest benefits of 3D printing in medical manufacturing. Off-the-shelf devices may not fit or function properly due to human anatomy. Using CT scans or MRI images, manufacturers can design products that match the patient’s anatomy using 3D printing technology. These products include personalized prosthetics, orthopedic implants, dental implants, and surgical guides. Customization of medical devices can improve fit, comfort, and efficacy, thereby improving patient satisfaction and treatment outcomes.

Faster Prototyping, Faster Time to Market

Speed is key in medical device development. Traditional manufacturing methods require a lot of preparation time to create molds or tooling before production. 3D printing eliminates many of these processes by printing parts from CAD files. Designers and engineers can use rapid prototyping to perform multiple tests and adjustments before final production. Faster development cycles enable new products to meet urgent clinical needs and help medical professionals more quickly.

Resource Optimization and Cost Efficiency

3D printing can reduce material waste and tooling costs. Traditional subtractive manufacturing throws away many raw materials. Additive manufacturing reduces waste and creates durable parts by using only the materials needed. Because 3D printing does not require molds or tooling, start-up costs are lower. This is especially true for small-volume or custom devices, which are too expensive to produce conventionally. As a result, 3D printing can make innovative medical devices more affordable and accessible.

Complex Design, Functional Integration

3D printing enables highly detailed designs that combine multiple functions into a single component. Medical devices can use internal channels, porous materials, or lattice structures to promote bone growth, reduce weight, and increase flexibility. This design freedom allows manufacturers to create implants that mimic the properties of natural tissue or more powerful surgical devices. This innovation can improve device performance and patient outcomes, advancing medical technology.

On-demand Local Production

On-demand production using 3D printing can reduce inventory and storage costs. Hospitals and medical facilities can produce parts when needed, without mass-producing defective equipment. The ability to quickly produce critical equipment or replacement parts locally is extremely useful in emergency situations or when supply chains are disrupted. Decentralized production reduces transportation costs and lead times, brings medical devices closer to healthcare, and improves global accessibility.

Material Innovations and Biocompatibility

3D printing technology has developed rapidly recently and now includes biocompatible plastics, metals, ceramics, and bioinks for tissue engineering. Modern materials science makes it possible to produce implantable or durable implants that are structurally strong, safe, and reliable. Titanium alloys used in 3D-printed implants are strong and biocompatible, while some polymers are flexible or biodegradable. These material developments enable applications in medical devices and next-generation healthcare solutions.

Surgical Planning and Education

3D printing technology is also changing medical education and surgical planning. Before surgery, surgeons can use 3D-printed anatomical models based on patient image data to observe complex surgical situations and practice operations. This hands-on preparation can reduce surgical risks and improve surgical precision. Realistic models can help medical students and professionals learn about anatomy and pathology. These applications demonstrate how 3D printing technology can impact medical services and education beyond the production of medical devices.

Future Opportunities and Challenges

3D printing has a bright future in medical device manufacturing. Researchers are studying bioprinting technology that can print living cells to create transplantable tissues and organs. These developments could transform regenerative medicine and personalized medicine. Material limitations, printing speed, and scaling up production for clinical applications remain challenges. Overcoming these barriers and realizing the potential of the technology will require further research, collaboration between industry stakeholders, and evolving regulations.

Conclusion

3D printing adds customization, speed, complexity, and cost-effectiveness to medical device manufacturing. The technology enables patient-specific implants, rapid prototyping, and on-demand manufacturing, improving accessibility and effectiveness. Material and design flexibility enhance device functionality, while surgical planning and education expand the impact of 3D printing in healthcare. Despite regulatory and technical barriers, 3D printing will have an impact on medical device manufacturing and patient care in the coming years.

FAQs

1. Can 3D printing reduce manufacturing costs?

3D printing reduces costs by reducing material waste, eliminating molds, and enabling on-demand manufacturing.

2. Is 3D printing just for prototyping?

Prototyping is a great use for 3D printing, but it’s also enabling the use of many medical devices in clinics.

. What materials are used in 3D-printed medical devices?

In tissue engineering, biocompatible polymers, titanium, ceramics, and bioinks are widely used.

4. What are the benefits of 3D printing in surgery?

Preoperative planning using patient-specific implants and anatomical models can improve surgical precision and reduce complications.

5. What are the barriers to medical manufacturing with 3D printing?

Challenges to large-scale production include regulatory approval, material limitations, production speed, and scale.